7 Advantages of Working With a USA Injection Molding Company

June 27, 2025Differences Between Closed Molding vs Open Molding

October 1, 2025If you’ve developed a product or part and are researching fabrication options, you’ve probably come across different methods and materials, each with pros and cons. Determining what will best suit your requirements, application, and budget can be challenging.

One plastic manufacturing process — reaction injection molding (RIM) — is gaining popularity because it can deliver a strong yet lightweight part, often at a lower cost than alternative processes.. Learn more about the RIM manufacturing process in this beginner’s guide to see if it might be right for your next project.

What is RIM?

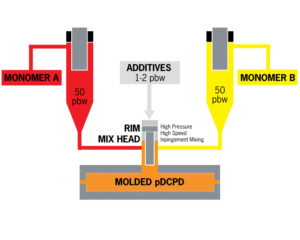

The basics of RIM are simple: It combines liquid resins into closed molds to produce plastic parts.

The resins are stored in separate tanks. When the manufacturing process begins, the resins are pumped into a mixing chamber. The pressure and speed at which they’re combined starts a chemical reaction that bonds molecules from the two resins. The resulting mixture is immediately injected into a closed mold, where the chemical reaction continues, and the newly formed material — a thermoset plastic — cures, or hardens, into the desired shape. (Thermoset plastic refers to plastic that cures through heating.)

The entire process can take as little as a few seconds or a few minutes, depending on the size of the part.

Benefits of RIM

In addition to forming strong yet lightweight parts, RIM molds can be complex, meaning the designs can have more complicated shapes or geometries. Not all manufacturing processes can support the same level of detail.

Because the RIM process doesn’t take a long time, you can quickly create prototypes and manufacture parts.

RIM is a great option if you don’t have a large production run. Because the initial tooling investment is fairly low, RIM is ideal for medium-sized quantities.

Lastly, RIM is versatile. It can produce rigid or flexible parts, depending on the materials used.

Materials Used in RIM

Polyurethane is one of the most common types of plastics found in RIM, but other thermoset plastic options include dicyclopentadiene (DCPD) and polyimides. These materials are very durable. They’re resistant to corrosion and impact, and they can withstand high temperatures and other harsh conditions. Osborne specializes in thermoset plastic molding, and many of the products we make are for original equipment manufacturer (OEM) parts, which often call for the strength these plastics can provide in the field.

Applications of RIM

Thanks to the versatility and durability found with RIM products, it’s used in a variety of industries.

Thanks to the versatility and durability found with RIM products, it’s used in a variety of industries.

- Automotive, agriculture, military, and construction: Fenders, bumpers, dashboards, and other heavy-duty equipment panels

- Medical: Enclosures for equipment such as MRI machines

- Industrial: Machinery housing

- Furniture: Custom parts, such as for gaming chairs

- Consumer: Housings for appliances such as refrigerators and air purifiers

How RIM Compares to Other Molding Processes

RIM can support complex designs, results in strong parts, and can accommodate low or medium production volumes. See how these features stack up against other manufacturing methods.

- Standard injection molding is when plastic pellets — thermoplastics — are melted and injected into a mold under high pressure. This can also produce strong parts but is better suited to larger production runs than RIM. RIM requires a lower tooling investment, making it a cost-effective option, especially for lower volume production.

- Blow molding is used for manufacturing hollow products. In this process, thermoplastics are heated, then air forces the pliable plastic into the sides of the mold. These designs are typically less complex, and the products are not as strong as those made using RIM.

- Rotational molding, also called centrifugal casting, is when plastic in powder form is placed inside a mold. Then the mold is heated and rotated, so the plastic sticks to the sides. This process is also used to make hollow items. Like RIM, this process supports lower production volume, but the parts are not as strong.

- Compression molding uses thermoset resins, which are heated and compressed in a mold. This process is better suited to making simpler forms, while RIM allows for more design freedom.

- Thermoforming is when a plastic sheet is heated then formed onto a mold using positive (gauge) or negative (vacuum) pressure. These parts are simpler in design and not as strong as those produced using RIM.

All these methods use closed molds. (Thermoforming can use closed and open molds.) Because closed molds completely encase the plastic, the final products don’t have a rough surface that requires finishing. Products made with closed molds are more consistent right off the production line and result in less waste.

As you continue to research the RIM process, you’ll want to dive deeper into details. Osborne Industries provides specs for the machines and presses we use for our RIM clients.

Partnering with a Manufacturer

When you’re ready to get started, look for a manufacturer who will consult with you on your project. Osborne has been manufacturing plastics for over 50 years. Our experts can provide guidance and offer innovative solutions.

To discuss your project with a specialist, fill out our contact form, and we’ll get in touch to understand your needs and determine next steps. If you’re ready to start your project, request a quote for manufacture at Osborne.